In this article composed by Kevin Garcia, Trimble General Manager, Civil Specialty Solutions; Riley Smith, Trimble Marketing Director, Monitoring and Tunnelling; and Doug Reichard, Trimble Director, Industry Strategy – State/Federal Government, we explore 3D technology’s role in ageing bridges.

The 2021 American Society of Civil Engineers (ASCE) Infrastructure Report Card gave US bridges an overall grade of ‘C’ as the lifespans of these critical structures come to an end and prior performance standards prove inadequate due to increased traffic volumes and heavier weight loads. To address this growing threat, the industry is adopting improved methods of inspecting, monitoring and constructing bridges, including scanning and mapping technology that provides valuable insight into the challenges associated with ageing infrastructure and the safety of transportation networks.

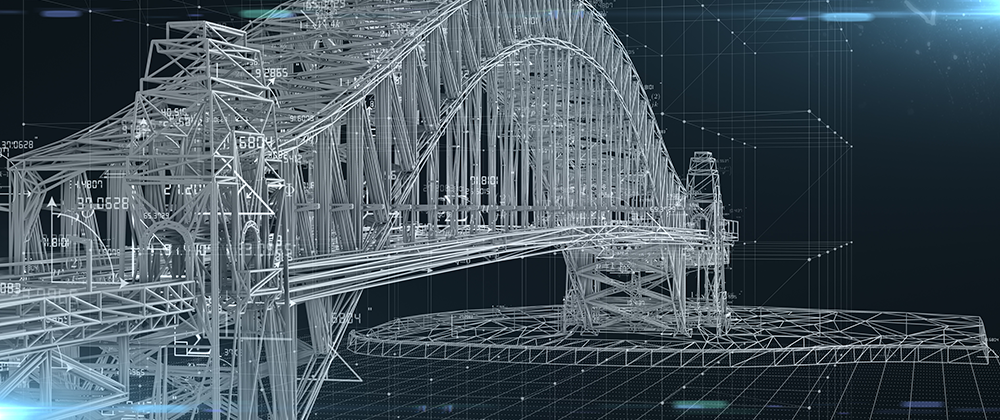

The dismal condition of thousands of bridges is driving the demand for accurate asset data to gauge current conditions, prioritise public safety and compare options for rehabilitation versus new construction. With the adoption of 3D bridge building information modelling (BIM), state departments of transportation (DOTs), government agencies and contractors are addressing this crisis with improved end-to-end asset lifecycle management.

The Kentucky Transportation Cabinet (KYTC) provides an illustrative example of how digital technology is playing a critical role in addressing failing bridges. In 2018, the Kentucky state legislature passed an ambitious highway plan, allocating US$350 million to renovate or replace 340 bridges over a two-year period.

“That was about five times more than we typically addressed in a single year,” said KYTC Programme Manager Royce Meredith.

With the accelerated timeline, KYTC turned to consulting partner Stantec, which helped the project team implement cloud-based construction management software to handle the bridge projects. The robust capital programme and construction management software allowed the team to streamline each phase of the process—from screening to developing plan specifications and estimates, bidding, and project management.

“We developed a full, connected project workflow for KYTC from screening through project closeout in Trimble e-Builder—all in less than a year,” said Dr Tony Hunley, Stantec’s Bridge Practice Leader. “To date, that workflow has been utilised on more than 400 bridges.”

Unique challenges posed by bridges

Bridges are a critical part of our transportation network; however, their complex and often hard-to-reach structures make frequent inspections difficult and costly. Even temporary closures cause disruption to normal traffic flow and supply chain routes, and if issues are identified, closing bridges for repair or replacement can cause even bigger problems. By streamlining workflows during the design, planning and construction phases, project managers seek to reduce inconvenience and cost, and respect the project delivery schedule. Additional benefits include compliance with rules and regulations, reducing rework, and increasing safety for both workers and bridge users.

Capturing the digital data of existing bridges using laser scanners, total stations, drones and Global Navigation Satellite Systems (GNSS) helps expedite surveying and provides data sets that are easily shareable between several departments. By creating a bridge BIM, all relevant data acquired can be integrated with information from various sources to evaluate the bridge’s condition and maintenance needs. This detailed model helps support informed decision-making and prioritises future work activities.

In the US, federally funded projects must meet certain sustainability requirements that emphasise best practices to reduce resource use, avoid change orders, and improve communication between stakeholders. To ensure compliance, state DOTs need effective ways to monitor contractor progress and quality of work. Bridge BIM data fills this need during construction and throughout the lifecycle of the asset.

In regions where winter weather shortens the construction season, large-scale projects must be started and completed within a limited timeframe. This finite window for field work limits the number of projects a contractor can complete. Streamlined workflows based on accurate data help prevent errors and delays and can significantly boost contractors’ productivity and profitability.

For specialist measurement agency OR3D, 3D laser scanners are a game changer. When sub-millimetre accuracy was required to create a complex digital twin of a damaged swing bridge, they used a 3D laser scanner to collect 120 scans in a single day. The digital twin was then converted to a 3D CAD model and used in software to simulate the motion of the bridge.

The ability to quickly achieve sub-millimetre accuracy was “…imperative for the project and made the job possible by beating the incoming tide,” said Robert Wells, service manager for OR3D.

Digital is trending

The effort to go ‘paperless’ is leading smarter bridge development while empowering effective asset lifecycle management from the pre-design phase through operations and maintenance. On new construction projects, as demonstrated by the impressive Randselva Bridge in Norway, forgoing 2D drawings and preparing all designs in a 3D model saves time and allows for simple, cross-departmental access to detailed project data. In a bridge BIM, every inch of the bridge is documented, down to each section of rebar, to use as a reference during construction and for ongoing maintenance. During construction, machine control software can follow digital bridge BIM instructions, which reduces errors, increases productivity and reduces waste of materials and emissions.

Digital workflows also benefit surveyors and contractors who remain under pressure to deliver results with speed and accuracy during inspections. Faster digital surveying tools, such as 3D laser scanners and mobile mapping systems, reduce the time needed for data collection. These highly accurate digital data sets support better data-driven decisions for allocating budget, prioritising critical cases and establishing effective monitoring systems to deliver critical real-time data during construction and operations.

To build an effective bridge BIM, interoperability is critical to allow the integration of data from multiple sources and different applications. Combining optical and scanning technology with geographic information system (GIS) information, bathymetry, drone imagery, etc., provides a higher level of detail and a better understanding of non-structural threats, such as flooding. With complete and accurate data encompassing the site and the surrounding area, change detection, design changes, materials and cost estimations, torsion analysis and other reports can be quickly generated and shared.

Additionally, digital recordkeeping allows plans to be updated and changed without producing multiple sets of paper blueprints that quickly become obsolete. Recently introduced, the Trimble Reality Capture platform service (TRCPS) improves collaboration by storing, managing and sharing large volumes of data in the cloud to ensure a single source of truth. By combining reality capture data, layout data, designs, panoramic images and other information together, a holistic view of the project is created in one easy-to-use interface.

New and improved methods

From the contractor perspective, digital workflows increase efficiency, save time, and improve productivity, while the owner benefits from a continuum of information that helps make future decisions that reduce the total cost of asset ownership. For example, in the end-to-end Trimble ecosystem, data flows from Tekla® design tools into Trimble Access™ field software, then Trimble Roadworks machine guidance software handles excavating and paving. Contractors can also automate data to flow back into the ecosystem for owners to use for operations and maintenance activities in software like Trimble Agile Assets. Leveraging bridge BIM modelling helps add additional value at every stage of the bridge design and construction process.

With the emphasis on doing more with less, it is imperative for organisations to reevaluate all workflows and implement best practices that improve efficiency and conserve resources. The industry is evolving rapidly, and project delivery is improving as stakeholders embrace model-based design and construction. This shift offers numerous benefits, from optimised designs and accurate material quantification to comprehensive as-built data that supports long-term asset management. A commitment to digital data capture and increased cooperation between design, construction and operation processes will help address the growing challenges of ageing road and rail bridge infrastructure. And hopefully soon earn the US a better grade.