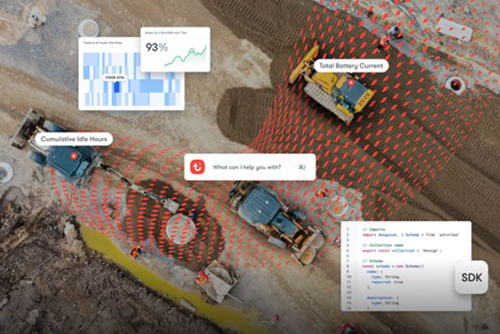

Fully integrated hardware, fleet management software and telematics ensure that Trackunit, with the Cisco platform, on AWS cloud provides a leading SaaS-based Internet-of-Things (IoT) solution for the construction industry.

Unplanned downtime causes a negative impact on project timelines and profitability and can irreparably harm construction companies. This downtime is particularly difficult to avoid when large, complex machines are involved in each construction project.

Key to construction technology’s acceptance is its ability to reduce downtime across construction projects.

Knowing the state of each machine at all times-including location, fuel level, hours of operation, engine temperature, tire pressure, and other telematics, can greatly improve downtime prevention. How can construction companies acquire this data, especially when they have a multitude of projects and fleets of machines spread across a variety of locations?

Getting individual operators to track and log machine information is challenging and error-prone, and you cannot collect it fast enough to act on it.

To solve this dilemma, Trackunit developed an industry-leading solution that easily connects construction assets, nearly anywhere in the world and gathers machine-specific telematics in real time.

The solution uses Cisco IoT Control Center to provide automation, analytics and proactive alerts that reveal potential problems before they occur and result in downtime. The system uses non-steered SIM cards from KPN IoT, a European telecommunications leader, to automatically and securely connect Trackunit devices primarily to LTE-M (4G) networks around the globe without operator intervention. Based on the type of module in the devices, they can also link to 3G and 4G networks and are able to connect to 5G as this capability continues to rolls out.

“Globally connected solutions are like chains with many links, and they are only as reliable as the weakest link” said Trackunit’s Daniel Conradsen. “There are several interconnections between our solution, KPN IoT’s global solution, and Cisco’s IoT platform. The ability to automate all of them is highly valuable to us and our customers.”

According to Trackunit, construction companies that connect at least half of their fleet financially outperform companies that do not by 23%. And companies that connect three-quarters or more of their fleet outperform the others by 51%.

The automation and simplicity of the solution have been key to the rapid growth of Trackunit’s customer base. Furthermore, more than 2.5 million machines and other construction assets are now connected and tracked with the company’s solution.

“We would not be able to meet such a high customer demand without automated connectivity and zero-touch processing,” said the IoT Operations Team Lead, Conradsen. “KPN IoT has stripped away complexity and simplified everything for us and our customers.”

That includes a single rate for cellular connectivity and data consumption, with 95% global coverage.

“We support thousands of connectivity and data patterns around the world,” Conradsen added. “Having a single rate plan and one invoice for all of them is super useful.”

With regulatory requirements becoming more stringent, Trackunit has expanded its solutions capabilities to enable the collection of additional data sets that are helping its customers with compliance and reporting, including Off Highway Vehicle (OHV) CO2 emissions.

In a Trackunit 2024 Survey on Construction’s Sustainability, 49% of respondents stated sustainability as Important or Very Important. The report gathered 13,000 questionnaires from across construction, demonstrating a clear move toward the industry becoming more efficient. Of companies with operating income over Euro 50 million annually, 60% were in that category.

“Through our devices and systems Trackunit is able to track information related to emissions and safety, which is becoming increasingly critical for customers” said Conradesen. “The system utilises the Cisco IoT Control Center which is an excellent data and connectivity management platform. It just works.”

With one-third of the Trackunit’s spending going on research and development, this provides users with the tools that immediately enable them to take better decisions underpinned by data-led insights on being more sustainable, reducing risk and leveraging efficiencies that can unlock value.

Trackunit’s rapid growth and future trajectory are very different from a decade ago, when the company was first investigating reliable technology partners and platforms.

“We have never been more satisfied with our connectivity or the underlying IoT platform,” Conradsen added. “The collaboration with KPN IoT and Cisco has been fantastic, transparent and open. We work together to support our customers, and there are no weak links in the chain.”

Connected equipment and systems are reducing vehicle and operator downtime on sites and in rental and vehicle yards. Faults and technology-led preventive maintenance checks on machines are making a real difference. Faults are flagged and the level of the problem analysed, and pre-emptive action taken to reduce downtime to a minimum. This connectivity allows owners and rental yards to schedule the machine into the workshop, ordering replacement components and ensuring minimal disruption to the rental contract and onsite work processes.