In the ever-evolving construction industry, the quest for workplace safety remains paramount. In this segment, we consult with experts to unravel the potential of emerging technologies in bolstering safety standards.

From advanced weather monitoring systems to wearable devices, technology stands poised to revolutionise safety protocols. Join us as we explore the innovative frontier where digital advancements converge with traditional safety practices, promising a future where construction sites are safer and more efficient than ever before.

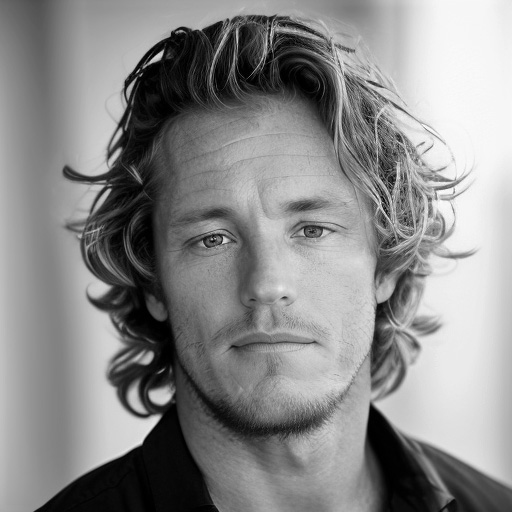

D. Scott Risch, VP of EHS at Rosendin

At a time when the labour market is stretched thin and workloads are at an all-time high, there has never been a greater need for the implementation of technology. When properly used, technology can ease the administrative burden placed on safety professionals, allowing them the opportunity to spend more time in the field or plant environment, doing what they love – keeping people safe. Technology can also be used as early warning devices, communicating things that we may be unaware of. For example, when weather stations detect an approaching storm, safety professionals know to take the next 15 minutes to activate severe weather protocols such as lowering crane booms, stopping exterior operations, securing materials, and preparing crews until storms safely pass. Personal devices can also be worn that monitor core temperature, speed, height and angle could potentially detect when someone is putting their body in a compromising position. There is even a personal electrical proximity alarm that can be worn to provide advanced warning when there is a threat of electrical exposure. Most of these devices are in the early stages of development, but in the future, they will be smaller, more affordable, and integrated into the safety gear we are already wearing. Technology has come a long way and it’s exciting to be able to be a part of progress every day. The future is exciting.

Joel Hutchines, Chief Product Officer at Slate Technologies

Emerging technologies are revolutionising workplace safety in the construction industry, particularly within Industrialised Construction (IC), where automation and robotics play a significant role. By reducing the need for manual labour and tackling repetitive and labour-intensive tasks, these technologies inherently enhance safety on construction sites.

In IC, the utilisation of robotics and automation not only streamlines processes but also minimises the risk of human error and injury. This shift towards automation prompts a fundamental rethinking of traditional construction methods. For instance, the design of materials like bricks, initially optimised for manual handling, now requires adaptation to maximise their potential within automated workflows, thus enhancing safety protocols.

Another pivotal aspect is the integration of computer vision and Artificial Intelligence (AI). These technologies are adept at identifying potential hazards in real time, thereby alerting relevant personnel promptly. Through continuous monitoring and analysis, AI-driven systems can pre-emptively detect risks, mitigating potential accidents and ensuring a safer working environment.

Perhaps the most transformative potential lies in leveraging AI and data analytics. By amalgamating data from various sources, AI can discern patterns and correlations that may not be apparent to human observers. For instance, AI algorithms can identify trends associating certain tasks or environmental conditions with heightened risks. This proactive approach enables stakeholders to anticipate and address safety concerns before they escalate into hazards, significantly reducing the occurrence of accidents.

The predictive capabilities of AI extend beyond individual sites. By analysing industry-wide data, AI can forecast emerging risks and trends, enabling proactive interventions at a systemic level. This holistic approach to safety management not only enhances on-site protocols but also informs broader industry standards and regulations.

In conclusion, emerging technologies are catalysts for transforming workplace safety in the construction industry, particularly within IC. Through automation, AI-driven monitoring, and data analytics, these technologies not only optimise efficiency but also prioritise safety. As the industry continues to embrace innovation, leveraging these advancements will be paramount in fostering a safer and more sustainable construction environment.

Cris Grossmann, CEO/Co-founder, Beekeeper

Emerging technologies have incredible potential to significantly improve workplace safety in the construction industry. Improperly maintained equipment not only risks downtime and expensive repairs but neglecting these processes can also greatly impact worker safety. When companies ensure that equipment is well-maintained, workplace accidents decrease. The maintenance and inspection of equipment is a crucial, yet often overlooked, aspect of ensuring workplace safety. Though these tasks can sometimes fall by the wayside, emerging tech can allow construction companies to automate these processes and provide a central repository of safety information easily accessible to all workers.

By automating maintenance and inspection processes, companies no longer need to rely on pen and paper to keep track of compliance processes. Solutions designed with frontline workers in mind can keep all team members up to date on when inspections or repairs are due. Beyond equipment, these systems can also help teams to plan and carry out safety audits regularly, making sure that construction materials and chemicals are handled properly, stored accordingly and that equipment is in proper working order.

Frontline success systems also enable companies to develop top-notch records of inspection, maintenance, and safety programs. Workers can conveniently use data, forms, and records to finish tasks, while digital workflow enhances quality, accelerates processes, and generates better business outcomes. When workers are on a site with limited reception or ability to interact with their teams, frontline systems serve as a valuable repository for safety information records, should workers need to access offline.

In the event that equipment does break down, workers can use frontline technology to immediately report the problem and communicate any safety concerns to everyone on site. With the whole team aware, workers can respond and adjust accordingly and managers can determine urgent needs and resolutions more efficiently. Managers can even get ahead of potential concerns by accessing analytics, such as how many maintenance jobs are pending and how long they take to fix, showing whether they need to hire more staff or approve extra hours to finish important tasks.

By doing preventive maintenance, construction companies can enhance workplace safety, boost morale and avoid legal troubles and costly settlements as a result of workplace incidents. Shifting from reactive to proactive maintenance through digitised processes boosts production, revenues and reliability while safeguarding frontline workers and creating a secure work environment.